Is ALL inventory 'waste'?

- Chad Bareither

- Dec 13, 2022

- 2 min read

In Lean we are taught of the seven deadly wastes (or eight depending upon your teacher/coach). The acronym TIMWOOD is often used as a memory device to recall the forms as; Transportation, Inventory, Motion, Waiting, Over-processing, Overproduction, and Defects. Whether you learned the acronym as TIMWOOD, WORMPIT, TWO-DIME, or DOWNTIME; Inventory is one of the seven deadly wastes of a process. Inventory is either finished goods, components or raw materials (also think office supplies, reports, data, SharePoint files ...) that are not having value added to them. They are sitting. They are a sunk cost. But is it all 'waste'?

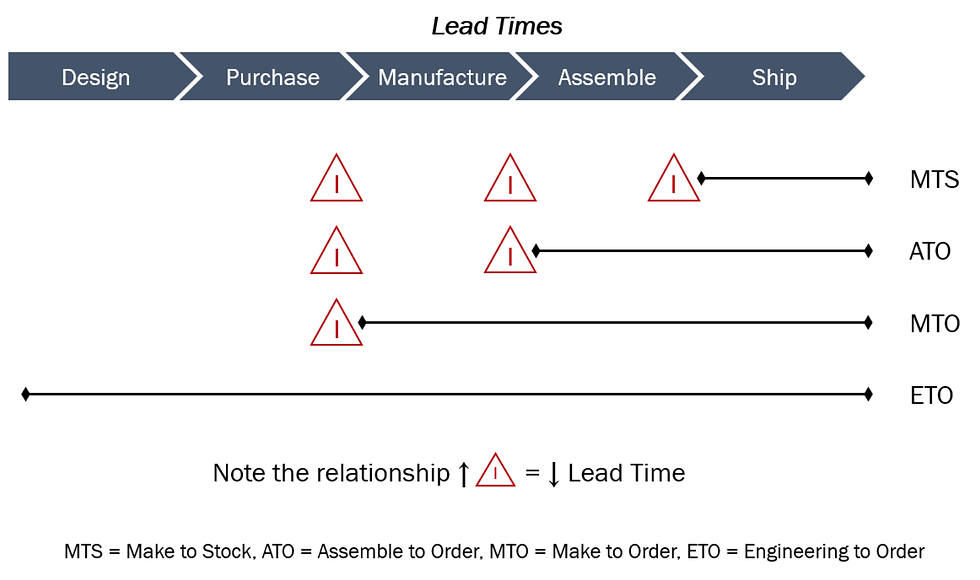

Inventory is a buffer against variation/disruptions in the business. Where you hold inventory along the value stream is an artifact of the business model you operate and the lead time you want to maintain for your customers (or rather, your customers expect). Shorter lead times are associated with more commodity products/services, like a newspaper (if anyone still read newspapers). On you way through the airport you may grab one at a news stand, but you wouldn't want to wait for one to be printed much less designed. This implies that inventory of the finished good needs to be held and, back upstream, papers, ink, banding strips, stories, columns and advertisements in components and raw materials. The variation/disruption in tat business that creates waste is fluctuating demand. After all, newspapers 'expire', so if we don't sell them today they are not worth much tomorrow. But! If we don't have them today we miss the sale.

There are two crucial elements to appropriately designing the supply chain and its associated inventory locations/levels. First, is awareness of the business model (indicated above). Second is understanding the source and magnitude of variations/disruptions. Inventory levels should be designed like resupply points for army caravans. Not developed due to misuse like plaque gathering in your arteries.

There is a second, strategic reason to carry inventory. That is when the risk of running our is greater than the cost to produce and carry extra. This is sometimes true in R&D settings or process development. The lead time to stop and produce more components or run a large scale batch costs more than producing extra in the first place. However, similar to the business model awareness above, this should be a decision by the business rather than a symptom of poor planning.

Inventory becomes a waste when it is covering up other problems. That could be poor quality, or ineffective planning, or an undefined business, or not understanding your risks. If you haven't decided upon how much inventory to carry, that is, it developed organically, there is a chance it glommed onto pain points in your process and you are not carrying the right amount.

Comments